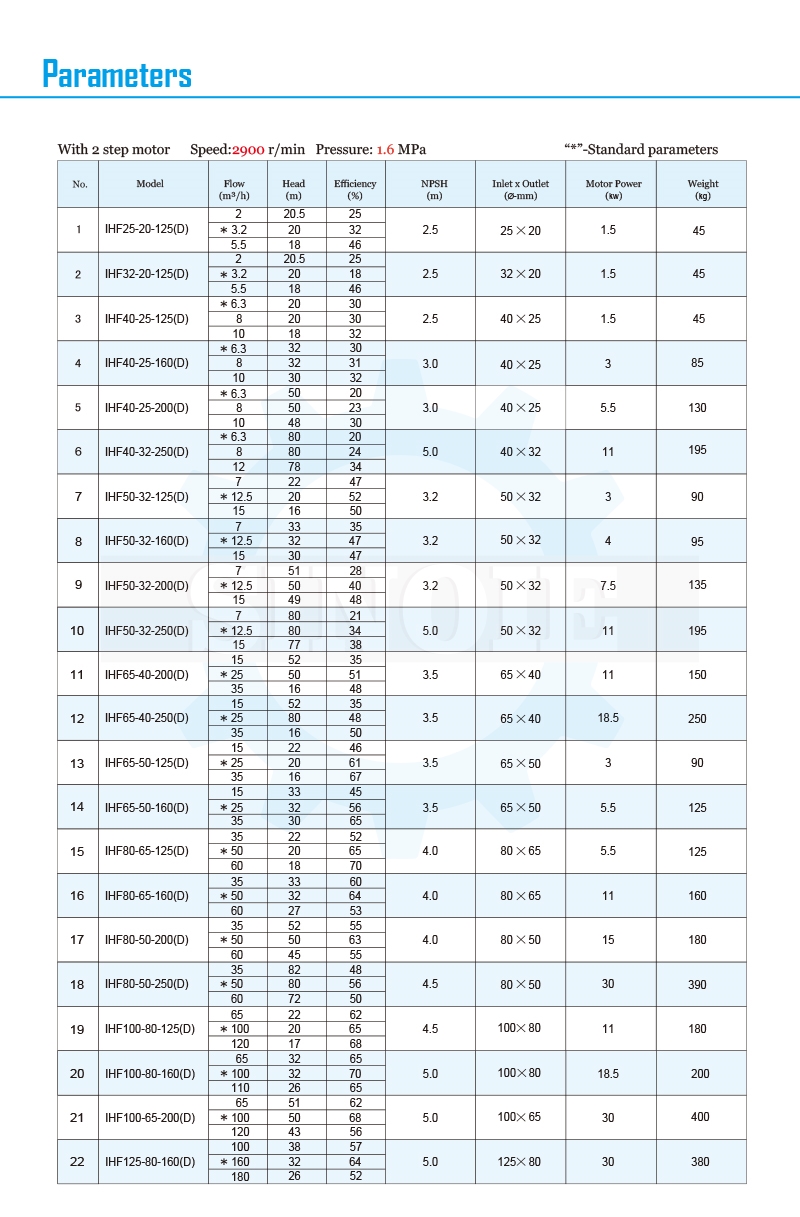

Working conditions:

Flow:2-180m³/h

Head:16-80m

Power:1.5-30kw

Range of working temperature:-20~100°C

Fluoroplastic alloy centrifugal pumps are designed for handling highly corrosive fluids, leveraging the exceptional chemical resistance of fluoroplastics.

Product features of these pumps:

1. Corrosion Resistance

- Material Composition: Made from fluoroplastic alloys (e.g., PTFE, PFA, FEP), these pumps are highly resistant to a wide range of corrosive chemicals, including acids, alkalis, and solvents.

- Wide Application: Suitable for industries like chemical processing, pharmaceuticals, and electroplating, where corrosive fluids are common.

2. High Temperature Resistance

- Fluoroplastic materials can withstand high temperatures, typically up to 150°C (302°F) or higher, depending on the specific alloy used.

3. Excellent Mechanical Strength

- The alloy construction provides good mechanical strength and durability, ensuring long service life even in harsh environments.

4. Non-Stick Properties

- Fluoroplastics have a low surface energy, making them non-stick. This prevents the buildup of deposits on the pump components, reducing maintenance needs.

5. Leak-Free Design

- Many models feature a magnetic drive or sealed design to prevent leakage, ensuring safe handling of hazardous or toxic fluids.

6. Lightweight Construction

- Compared to metal pumps, fluoroplastic alloy pumps are lighter, making them easier to install and transport.

7. Low Maintenance

- The corrosion-resistant and non-stick properties reduce wear and tear, minimizing the need for frequent maintenance.

8. Versatile Impeller Options

- Available in various impeller designs (open, closed, or semi-open) to handle different fluid types, including those with suspended solids.

9. Energy Efficiency

- Designed for optimal hydraulic performance, these pumps often operate with high efficiency, reducing energy consumption.

10. Customizable

- Can be tailored to specific applications, including variations in size, flow rate, and pressure requirements.

11. Smooth Operation

- The pump's design ensures smooth and quiet operation, reducing vibration and noise.

12. Compliance with Standards

- Many fluoroplastic alloy centrifugal pumps meet international standards for quality and safety, such as ISO and ANSI.

13. Wide Range of Applications

- Ideal for industries like chemical processing, pharmaceuticals, wastewater treatment, and semiconductor manufacturing, where corrosion resistance is critical.

14. Resistance to Abrasion

- Some fluoroplastic alloys offer good resistance to abrasive fluids, extending the pump's lifespan in challenging conditions.

15. Easy to Clean

- The smooth, non-reactive surface of fluoroplastics makes the pumps easy to clean and sterilize, which is essential in industries like food and pharmaceuticals.

Application fields:

- Chemical Processing Industry

- Applications: Transferring acids (e.g., sulfuric, hydrochloric), alkalis, organic solvents, and aggressive chemicals.

- Advantages: Resists corrosion, ensuring longevity in reactors, storage, and piping systems.

- Pharmaceutical and Biotechnology

- Applications: Handling corrosive reagents, high-purity solvents, and sterile processes.

- Advantages: Non-reactive materials prevent contamination, critical for drug synthesis and bioprocessing.

- Electroplating and Metal Surface Treatment

- Applications: Circulating acidic/alkaline baths (e.g., nickel plating, pickling solutions).

- Advantages: Withstands highly corrosive electrolytes and high-temperature baths.

- Environmental Protection and Wastewater Treatment

- Applications: Managing corrosive industrial effluents, acidic/alkaline sewage, and hazardous waste.

- Advantages: Resists abrasion from slurries and chemicals like chlorine or ferric chloride.

- Semiconductor and Electronics Manufacturing

- Applications: Transferring ultra-pure chemicals (e.g., etchants, photoresists).

- Advantages: Prevents ionic contamination, crucial for wafer fabrication and cleanrooms.

- Oil, Gas, and Petrochemicals

- Applications: Handling corrosive hydrocarbons, brine, and offshore seawater.

- Advantages: Suitable for sour gas environments (H₂S-rich) and refineries.

- Food and Beverage Industry

- Applications: Processing acidic products (citrus juices, vinegar) and CIP systems.

- Advantages: FDA-compliant materials ensure hygiene and corrosion resistance.

- Power Generation

- Applications: Cooling systems, flue gas scrubbing (e.g., sulfuric acid in desulfurization).

- Advantages: Resists high-temperature corrosive fluids in coal/nuclear plants.

- Mining and Metallurgy

- Applications: Transporting abrasive slurries with corrosive elements (e.g., leaching agents).

- Advantages: Enhanced wear resistance from alloy components.

- Agriculture

- Applications: Distributing fertilizers, pesticides, and herbicides.

- Advantages: Durability against corrosive agrochemicals.

Additional Applications:

- Desalination Plants: Handling seawater and brine with high chloride content.

- Pulp and Paper Industry: Managing corrosive bleaching agents (e.g., chlorine dioxide).

- Automotive: Coolant systems and battery acid handling.

The transportable mediums for these pumps typically include:

- Strong Acids:

- Hydrochloric acid (HCl)

- Sulfuric acid (H₂SO₄)

- Nitric acid (HNO₃)

- Phosphoric acid (H₃PO₄)

- Hydrofluoric acid (HF)

- Strong Bases (Alkalis):

- Sodium hydroxide (NaOH)

- Potassium hydroxide (KOH)

- Ammonium hydroxide (NH₄OH)

- Organic Solvents:

- Acetone

- Methanol

- Ethanol

- Toluene

- Chloroform

- Salt Solutions:

- Sodium chloride (NaCl)

- Potassium chloride (KCl)

- Ferric chloride (FeCl₃)

- Oxidizing Agents:

- Hydrogen peroxide (H₂O₂)

- Sodium hypochlorite (NaOCl)

- Other Corrosive Chemicals:

- Bromine

- Chlorine

- Iodine

- High-Purity Chemicals:

- Ultra-pure water

- High-purity acids and solvents used in semiconductor manufacturing

Key Features of Fluorine Plastic Alloy Centrifugal Pumps:

- Corrosion Resistance: The fluorine plastic alloy (such as PTFE, PVDF, or PFA) provides excellent resistance to a wide range of corrosive chemicals.

- High Temperature Resistance: These pumps can handle high-temperature fluids, depending on the specific material used.

- Leakage Prevention: The design often includes features to prevent leakage of hazardous or toxic fluids.

- Durability: The materials used are highly durable and resistant to wear, even when pumping abrasive fluids.

Applications:

- Chemical processing

- Pharmaceutical manufacturing

- Semiconductor industry

- Wastewater treatment

- Metal finishing and plating

- Dye and pigment production

Considerations:

- Temperature Limits: Ensure the pump materials are suitable for the temperature of the medium being transported.

- Concentration Levels: The concentration of the chemicals can affect the pump's performance and longevity.

- Abrasive Particles: If the medium contains abrasive particles, additional considerations may be needed to prevent wear.

In summary, fluorine plastic alloy centrifugal pumps are versatile and can handle a wide range of corrosive and hazardous chemicals, making them ideal for demanding industrial applications.

Sino Industrial Equipment Co., Ltd. is a leading manufacturer and supplier of high-performance chemical pumps and related equipment, specializing in solutions for the industrial, chemical, petrochemical, and water treatment sectors. With decades of experience in the field, the company has built a solid reputation for designing and producing pumps that offer durability, efficiency, and superior resistance to aggressive fluids.

Mission:

To provide innovative, reliable, and cost-effective pumping solutions to meet

the diverse needs of the global chemical, industrial, and environmental

markets. Sino Industrial Equipment Co., Ltd. strives to deliver products that

help businesses improve operational efficiency while ensuring the highest

standards of safety and environmental compliance.

Core Products:

- Chemical Pumps: Designed for the transportation of corrosive, abrasive, and high-temperature fluids. Available in a variety of configurations such as centrifugal, diaphragm, gear, and piston pumps.

- Centrifugal Pumps: High-capacity pumps widely used in industrial applications to handle large volumes of liquids.

- Magnetic Drive Pumps: Pumps featuring a hermetically sealed, non-leakage system ideal for transporting hazardous or toxic chemicals.

- Peristaltic Pumps: Ideal for metering, dosing, and transferring fluids that require high accuracy.

- Vertical Pumps: Tailored for applications with space limitations, these pumps are built to handle heavy-duty operations in harsh environments.

- Pump Accessories & Spare Parts: Including seals, gaskets, and control systems, ensuring long-term operational performance and reliability.

Key Features & Advantages:

- Durability & Reliability: Designed to withstand extreme temperatures, pressure, and corrosive environments, ensuring longevity in challenging conditions.

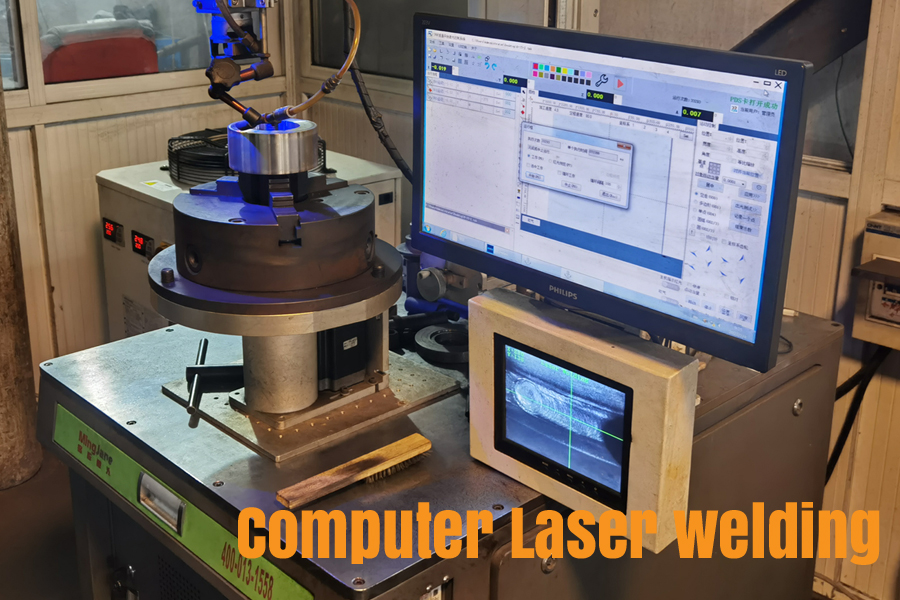

- Advanced Technology: Incorporating state-of-the-art materials and engineering techniques to enhance the performance and energy efficiency of each pump.

- Custom Solutions: Providing tailored pumping solutions to meet the unique requirements of clients across various industries.

- Commitment to Sustainability: Sino Industrial Equipment Co., Ltd. emphasizes environmental protection and sustainability in all of its manufacturing processes, ensuring minimal waste and a reduced carbon footprint.

Industries Served:

- Chemical Manufacturing

- Petrochemical & Refining

- Water Treatment

- Pharmaceutical & Biotechnology

- Food & Beverage

- Mining & Metallurgy

- Environmental & Wastewater Management

Quality Standards:

The company adheres to international quality standards such as ISO 9001, CE,

and other certifications, ensuring that all products meet stringent performance

and safety requirements. Each product undergoes rigorous testing to guarantee

reliable operation under the most demanding conditions.

Customer

Commitment:

Sino Industrial Equipment Co., Ltd. places a strong emphasis on customer

satisfaction, offering personalized service and technical support to ensure the

optimal functioning of its products. The company’s experienced engineers and

service team are readily available to provide consultations, system designs,

installation, and after-sales services.

Global

Presence:

With a growing presence in over 30 countries, Sino Industrial Equipment Co.,

Ltd. exports its products worldwide, meeting the needs of global customers in

various industrial sectors. The company continues to expand its international

footprint, establishing strong partnerships with distributors, suppliers, and

manufacturers.

Sino Industrial Equipment Co., Ltd. is a trusted partner in the industrial sector, known for its innovation, quality, and customer-centric approach. The company is committed to delivering cutting-edge, sustainable pumping solutions that contribute to the success and efficiency of industries worldwide.

Our

factory has 30 years and 60 years of manufacturing experience

for pump and motor separately.

We work closely with our customers to provide products that meet their

demanding specifications, quality and delivery requirements.

We welcome all inquiries and will answer any questions promptly. We will work

closely with you to facilitate the successful procurement of the orders you

place with us to provide a product that will be produced to your specifications

and quality requirements in a timely manner and reasonable priced.

Please contact us about your product interest (large or small qty) and any

relevant information.

We assure you of our immediate reply with the hope we can will develop and long

and profitable relationship together based on our performance and integrity.

.jpg)

Pump

-TMF series Fluorine plastic alloy magnetic pump

-CQB series Fluorine plastic alloy magnetic pump

-IMD series Fluorine plastic alloy magnetic pump

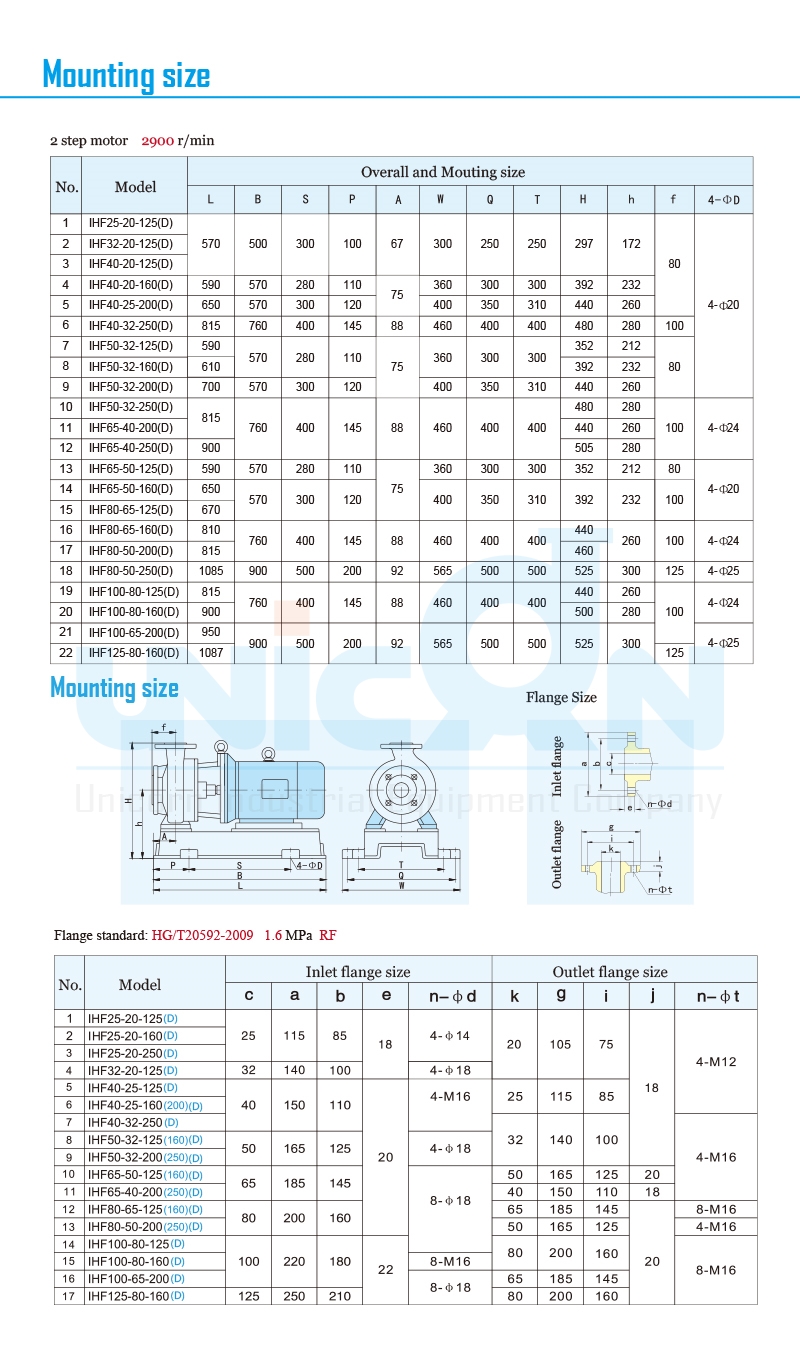

-IHF series Fluorine plastic alloy centrifugal pump(IHF,IHF-D)

-FSB series Fluorine plastic alloy centrifugal pump(FSB,FSB-D)

-ZMD series Fluorine plastic alloy self-priming magnetic pump

-ZFT series Fluorine plastic alloy self-priming magnetic pump

-FZB series Fluorine plastic alloy self-priming centrifugal pump

-CQ series Stainlsess steel magnetic pump(CQ,CQB-P,CQB-L)

-IH series Stainless steel centrifugal pump

-ZCQ series Stainless steel self-priming magnetic pump

-ZX/ZW series Stainless steel self-priming centrifugal pump

-GF series Fluorine plastic pipe pump(GF,GD-F)

-UHB-ZK series Fluorine plastic mortar pump

-FYH series vertical subliquid pump

-LG series Stainless steel screw pump

-BY series Pneumatic or electric diaphragm pump

-MYF-I series Wear resistant and corrosion resistant pump

-Fluorine plastic alloy valve

Motor

-High efficiency motor

-High voltage motor

-Explosion-proof motor

-Permanent magnet synchronous motor

-Frequency variable speed regulation motor

-Low voltage motor

-NEMA Standard motor

-Special purpose motor

-Single-phase induction motor

-DC motor

-High-speed motor

-Smart control motor

-New energy vehicle motor

Thank you for your kindly attention to our company.

Whatever if you are interested in our products or want to know more about your

interested products or want to collect industrial equipments products but with small

quantities, or need helps in China.

Let us know.

We are happy to reply you any inquiries and give your help as possible as we

can.

ARE YOU A

MANUFACTURER OR TRADING COMPANY?

We are not only a trading company, but also a manufacturer. Welcome to visiting

our factory.

WHY CHOOSE US?

Choosing the right supplier or partner is crucial for achieving your goals.

Expertise and Experience:

We backed by years of experience and a team of highly skilled professionals.Our expertise ensures that we deliver top-notch solutions tailored to your needs.

Reliablility and Trust:

Legally registered company in China and has many years of export business in the field of industrial equpments. Our commitment to transparency,integrity and timely delivery ensures a seamless experience every step of the way.

Cost-Effective Solutions:

We offer high-quality services at competitive prices,ensuring you get the best value for your purchase.

Low MOQ to Start Small Business

This allows you to order smaller quantities and reduce upfront costs.

Timely Reply

Establish clear communication channels(phone,email,whatsapp,wechat,skype etc.) to ensure quick replies.

Quality Guarantee

Request samples before placing a bulk order to verify technology.

Offer inspection service to ensure product quality before shipment.

On-time Delivery

Clearly communicate your deadlines and confirm our ability to meet them.

Continuously track and monitor delivery progress.

Better Service and Dedicated Support

Our team is always here to support you, whether it’s answering questions, troubleshooting, or providing ongoing guidance. We’re committed to your long-term success.

WHAT IS YOUR MOQ?

No MOQ is required.

CAN YOU SUPPLY SAMPLE WHEN PLACING BIG ORDER PROJECT?

Yes, we are happy to provide sample for testing.

However, the shipping cost from our company to your requested address will be borne by the customer.

We typically use UPS,TNT, DHL, FEDEX, or EMS for shipping. Delivery to many European countries and North America usually takes 3-6 days. You may choose the courier service based on your convenience or shipping cost preferences.

WHAT IS YOUR LEAD TIME?

General lead time: Typically 10-15 days, but this can vary depending on the specifics of your requirements and specifications.

If you have specific requirements or need a more accurate estimate, feel free to share more details with us.

CAN YOU MAKE CUSTOMIZED INDUSTRIAL EQUIPMENT?

Yes,we can make customized industrial equipments as clients required.

Whether you're looking for unique designs, or equipment that fits a particular use, we can work with you to develop a solution that meets your goals. We work closely with clients to design and build equipment that aligns with their goals, Let me know your requirements, and we can start the process.

WHAT INFORMATION SHOULD WE OFFER BEFORE YOU RECOMMEND SUITABLE PUMP?

Name of medium:

Range of Medium temperature:

Medium concentration:

Medium density:

Ph of Medium:

Midium viscosity:

Crystallize or not?

Does the Medium contain particles?

Particle size/ soft or hard?

Required flow range:

Required pump head range:

Required suction head range:

Variance of ambient temperature:

Position elevation

Voltage/Frenquenty/Power/Motor type/Motor speed etc.

The above details,we will send you a table for pump selection. Then please fill in the details and send it back to us.

According with the details, we will recommend you suitable pump for your further confirmation.

WHAT ABOUT THE WARRANTY?

12 months warranty, 6 months for wearing parts.

WHO WILL BE RESPONSIBLE FOR THE AFTER-SALE SERVICE?

Around the world, There is always a distributor nearby who

has factory-trained filed specialists to provide one-to-one services to you. If

not,we also have several professional after-sales service teams in China. We

will follow up the client's comments ,then help them get the best solution for

maximizing the equipment efficiency and plant maintenance needs.

For large order of big project, we can send our service team to go abroad to

assemble and test upon our clients requirements.

HAVE YOU DISPLAYED ALL OF YOUR PRODUCTS ON YOUR WEBSITE?

No, only a portion of our products are currently showcased on our website. If you are looking for other related products, please feel free to contact us directly, and we’ll be happy to assist you.

Customized Logos Welcome!

OEM Orders Accepted!

Buyer Designs Encouraged!

Http://www.sinoequipments.com

Http://sinoequipments.en.made-in-china.com

.jpg)